LTI offers a broad range of fastener testing and dimensional inspection to keep your business operating efficiently. Whether you order testing for raw materials and finished fasteners or research quality issues with production, you will benefit from identifying and correcting weaknesses or defects before costly problems occur.

Fastener Testing Services

Mechanical Testing

- Hardness Testing

- Magnetic Permeability

- Double Shear

- Yield Strength

- Wedge & Axial Tensile

- Proof Load Testing

- Tension Fatigue Test

- Cone Strip Test

- Flattening

- Creep Testing

- Stress Rupture Test

- Hydrogen Embrittlement / Stress Durability

- Washer Testing

- Free Height Test

- Compression

- Interlocking Test

- Twist Test for Locking Washers

Metallurgical Testing

- Grain Size

- Carburization / Decarburization

- Plating Thickness

- Surface Contamination

- Alpha Case

- Thread Examination

- Microstructure

- Macro-etch

- Grain Flow

- Microhardness

Chemical Analysis

- ICP Spectrometry (ICP-AES, ICP-MS)

- AES Analysis

- FTIR Analysis

- Carbon / Sulfur / Nitrogen / Oxygen / Hydrogen Determination

- Positive Material Identification (PMI)

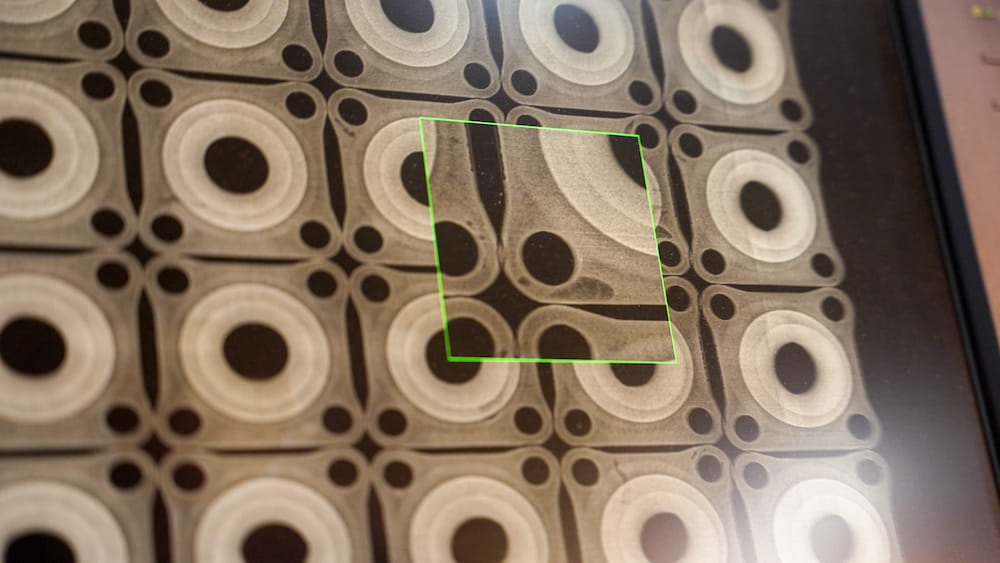

Nondestructive Testing

- Magnetic Particle Inspection

- Liquid Penetrant Testing

- Ultrasonic Testing

- X-ray Inspection (Radiography)

Dimensional Inspection

- Internal threads

- External threads

Fastener Testing Detects Defects

LTI Is a One-Stop Material Testing Lab

Test Methods/Specifications

- ASTM A370

- ASTM A962

- ASTM E112

- ASTM E340

- ASTM F2328

- ASTM F606

- ASTM F835

- SAE J429

- SAE J995

- ISO 898-1

- ISO 898-2

- NAS 1069

- NASM-1312-1

- NASM-1312-5

- NASM-1312-6

- NASM-1312-8

- NASM-1312-11

- NASM-1312-12

- NASM-1312-13

- NASM-1312-18

LTI Capabilities

- 100 to 600,000 lb. testing capacity

- Various chemical services to analyze, identify, and reveal material composition

- Verify the corrosion resistance of fastener coatings

- Identify surface-breaking discontinuities

- Dimension inspection adhering to NAS, MS, and ANSI specifications

The LTI Advantage

Request a quote or contact us today to see how LTI’s industry-leading turnaround times can keep your mission-critical approvals moving forward.