Often, the how and why of material failure is as critical as the when. Crack propagation in 3D bodies will undoubtedly be proportional to the force applied and the size/shape of the flaws. However, loading is complex, with a stress-strain matrix developing depending on the distance in space between the applied loading and material flaws, the material’s performance in tension versus compression, and other variables. Fracture toughness testing looks to quantify performance by destroying materials with increasing loading forces, studying the progression of cracks through failure.

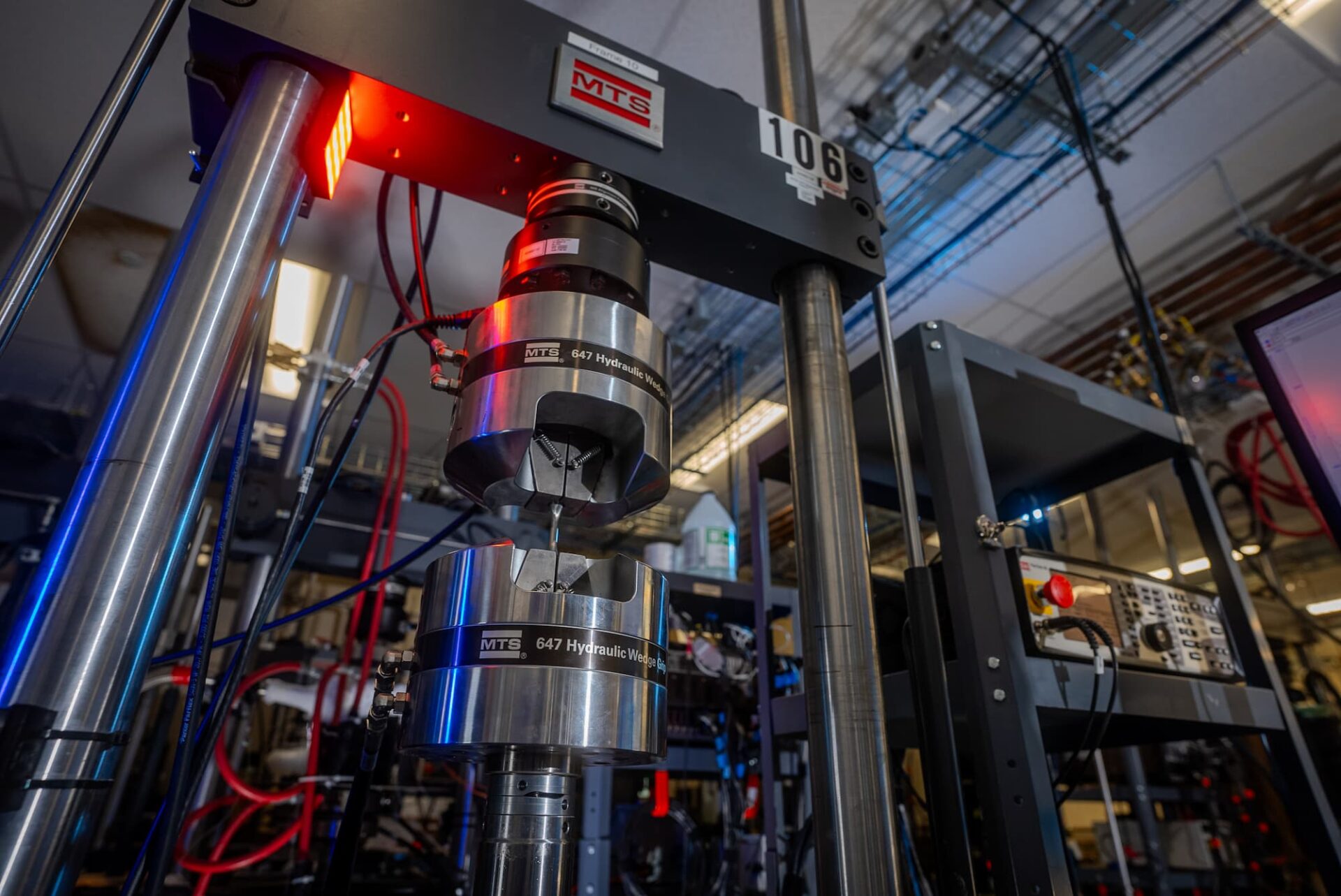

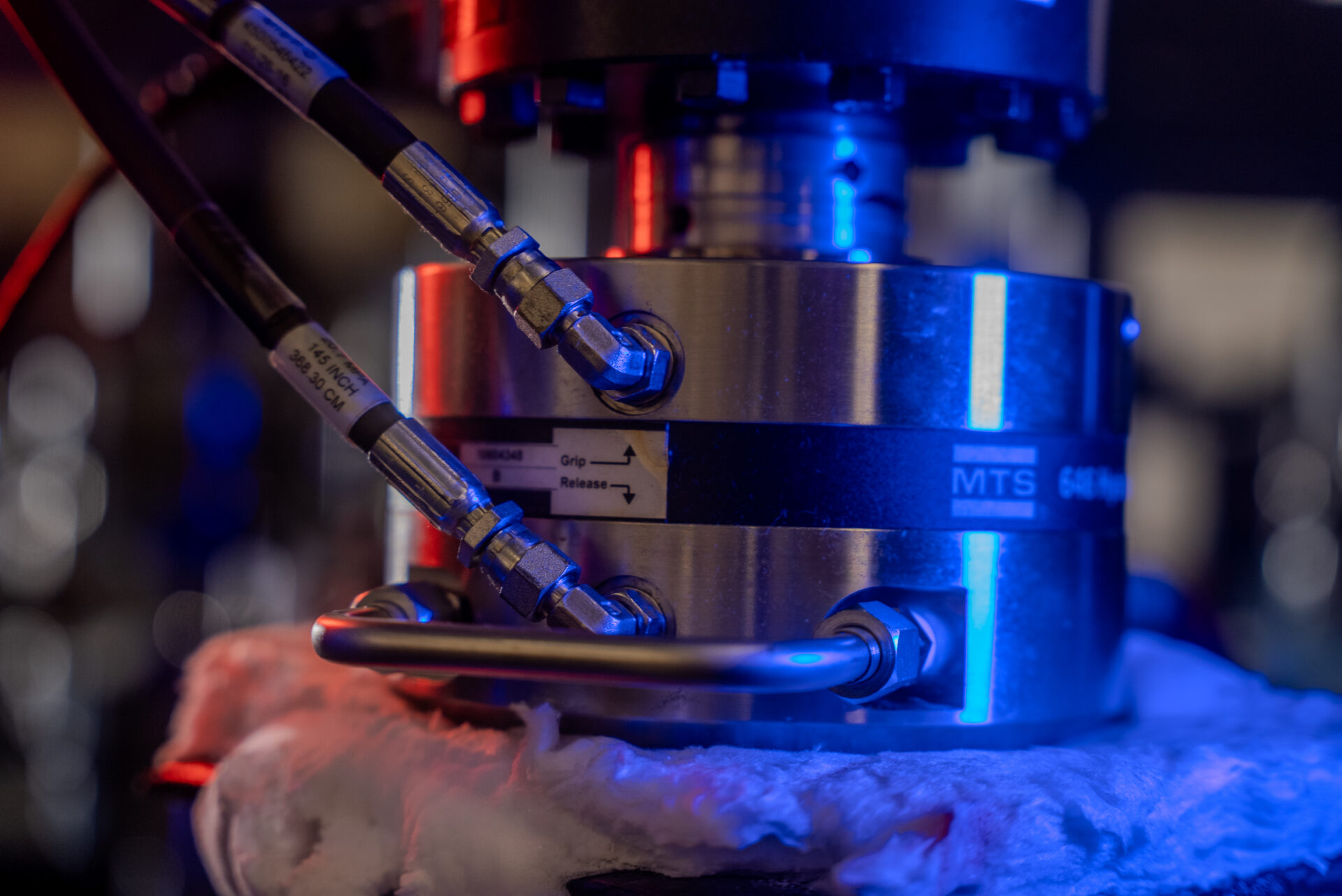

Fracture Toughness Testing at LTI

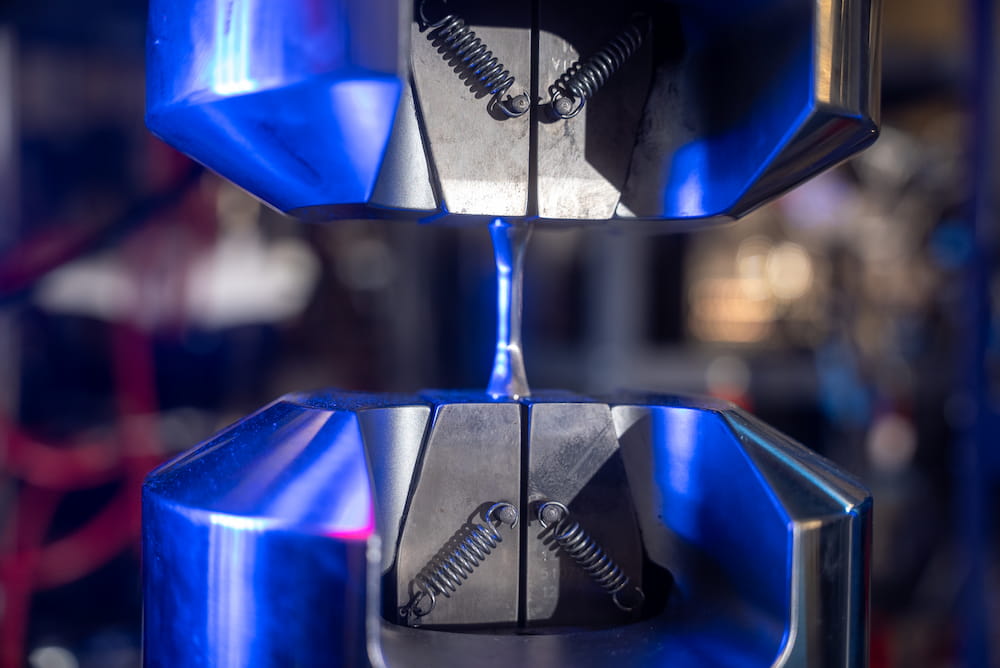

The fracture toughness test determines how well a material can resist the growth of a crack under an increasing load. During a fracture toughness test, a specimen with a pre-existing crack experiences a rising tensile load. By measuring the combination of load and displacement as the crack lengthens, the material’s resistance to further crack propagation reveals itself. Fracture toughness is an important material property in design applications since the occurrence of flaws is not entirely avoidable. Flaws may appear as cracks, voids, inclusions, weld defects, or design discontinuities. The fracture toughness test is also valuable in determining whether component failure is dangerous when a flaw is revealed in an existing structure.

Test Specimens Preparation by LTI

- Single Edge Bend (referred to as SE(B) or SENB) – a rectangular specimen with a slot cut in the long side, loaded in three-point bending

- Compact Tension (C(T)) – the most commonly used geometry

- Disk-Shaped Compact Tension (DC(T)) – necessary when a fracture toughness result is essential for the C-R direction of a round bar

- Specimen sizes ranging from Charpy-sized SE(B) bars up to 4.5” W C(T)

Capabilities

Standards

Having a Tough Time With Material Testing Logistics? Talk to LTI

Partner With LTI Today

Laboratory Testing Inc. has the capacity and capabilities to handle all your material testing needs in a single location. Since 1984, we’ve aided customers worldwide with accurate nondestructive testing and precise material lab services. Request a quote or contact us today to see how our industry-leading turnaround times can keep your mission-critical approvals moving forward.