Hardy, resilient, and malleable metal alloys provide foundational support to diverse components and industries. Metallurgical testing is necessary to understand how these metals function for processing and use. LTI provides multiple metallurgical analysis and testing modes to thoroughly characterize materials and products that adhere to industry standards and safety guidelines.

Metallurgical Testing for Thorough Characterization

Range of Services

Macroscopic Examinations

- Macro-etch (ASTM E340)

- Grain Flow

- Weld Qualification

- Surface Condition

- Fractography

- Digital Imaging

Microscopic Examinations

- Microstructure

- Carburization & Decarburization

- Grain Size (ASTM E112)

- Inclusion Rating (ASTM E45)

- Plating/Coating Thickness

- Carbide Precipitation

- Ferrite by Point Count (ASTM E562)

- Intergranular Attack & Oxidation

- Alpha Case

- Intergranular Corrosion (ASTM A262)

- Sensitization

- Surface Contamination

- Nodularity, Nodule Count

- Eutectic Melting

- Case Depth

Sample Preparation

- Precision Cutting

- 1.5″ & 2″ Mounts

- Thermoset & Thermoplastic Mounting

- Cold Mounting

- Non-Routine Mounts

- Automatic and Hand Grinding & Polishing

- Immersion, Swab & Electrolytic Etching

Microhardness Testing

- Case Depth

- Profiles

- Knoop & Vickers Testing

- Carburization & Decarburization

- Surface Contamination

Additional Services

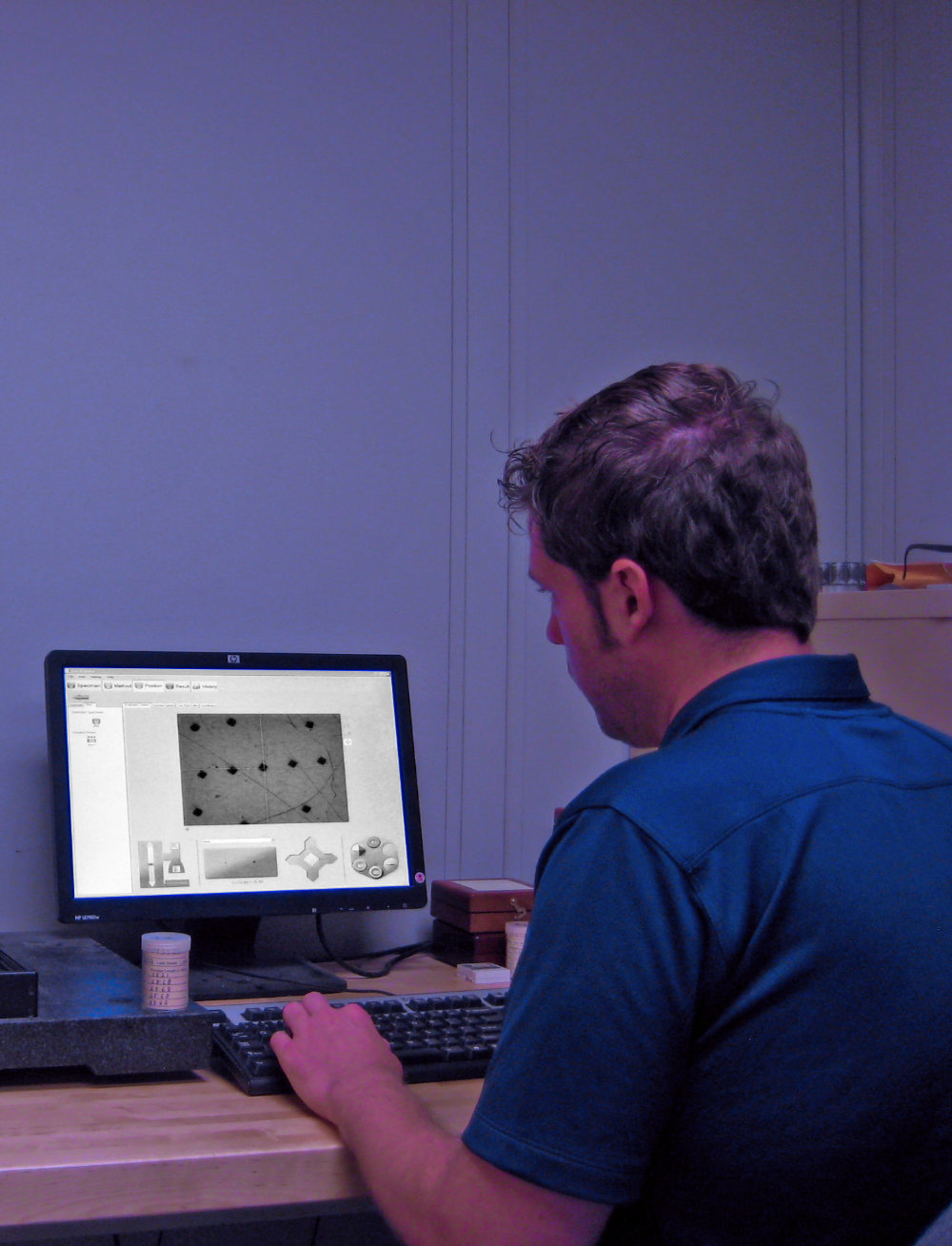

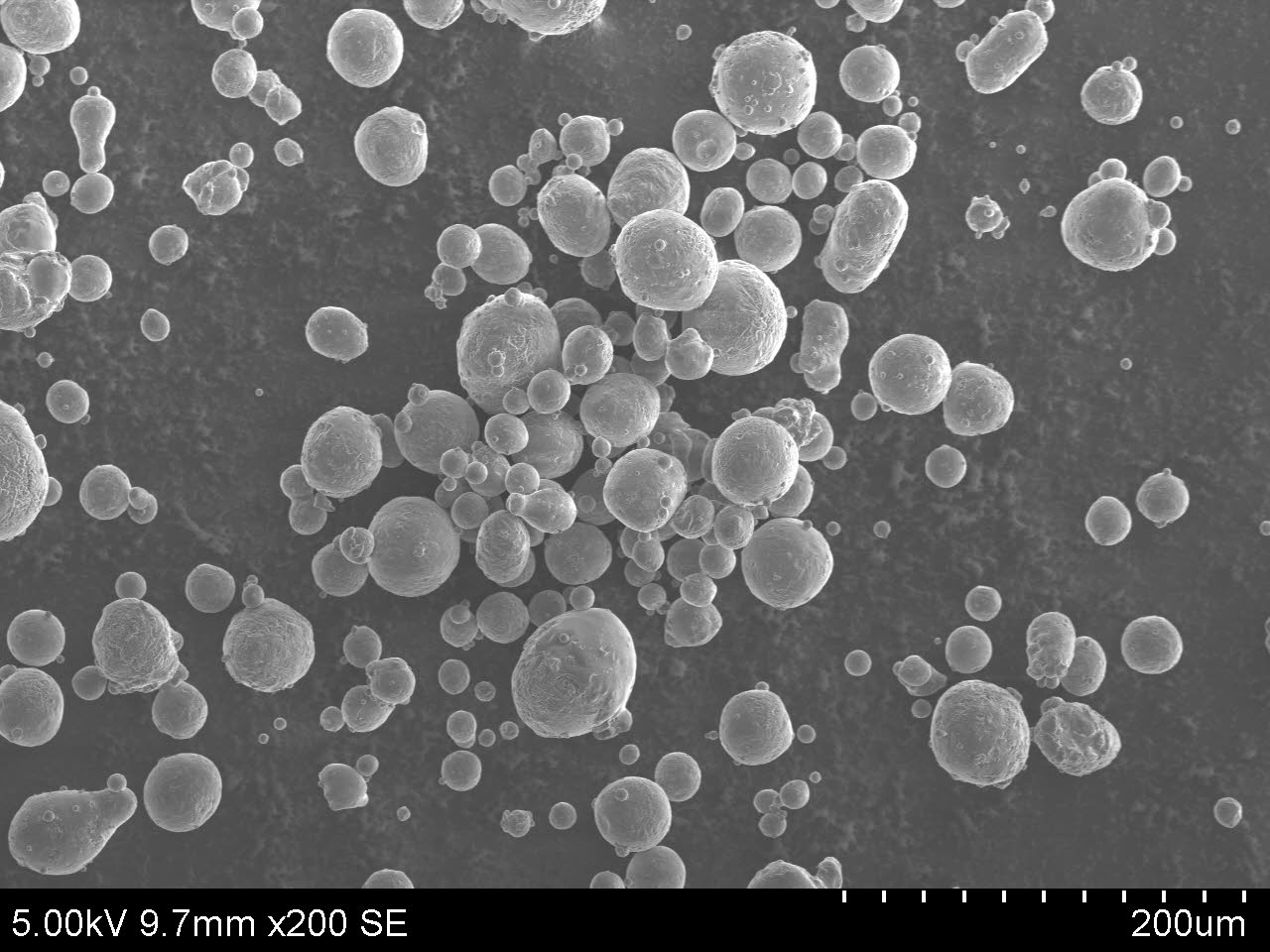

- Scanning Electron Microscopy (SEM/EDX)

- Digital Imaging

- McQuaid-Ehn Grain Size

- Welder and Procedure Qualification (adhering to MIL & API specifications, ASME & AWS codes, ASTM & EN standards, and the Pressure Equipment Directive)

Capabilities

The LTI Advantage

Partner With LTI Today

Laboratory Testing Inc. with the capacity and capabilities to handle all your material testing needs in a single location. Since 1984, we’ve aided customers worldwide with accurate nondestructive testing and precise material lab services. Request a quote or contact us today to see how our industry-leading turnaround times can keep your mission-critical approvals moving forward.