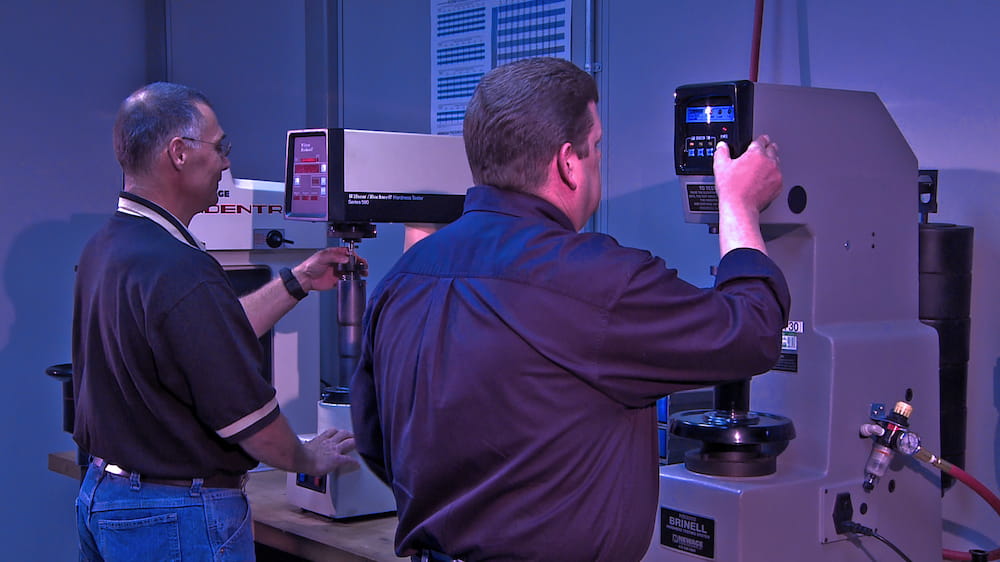

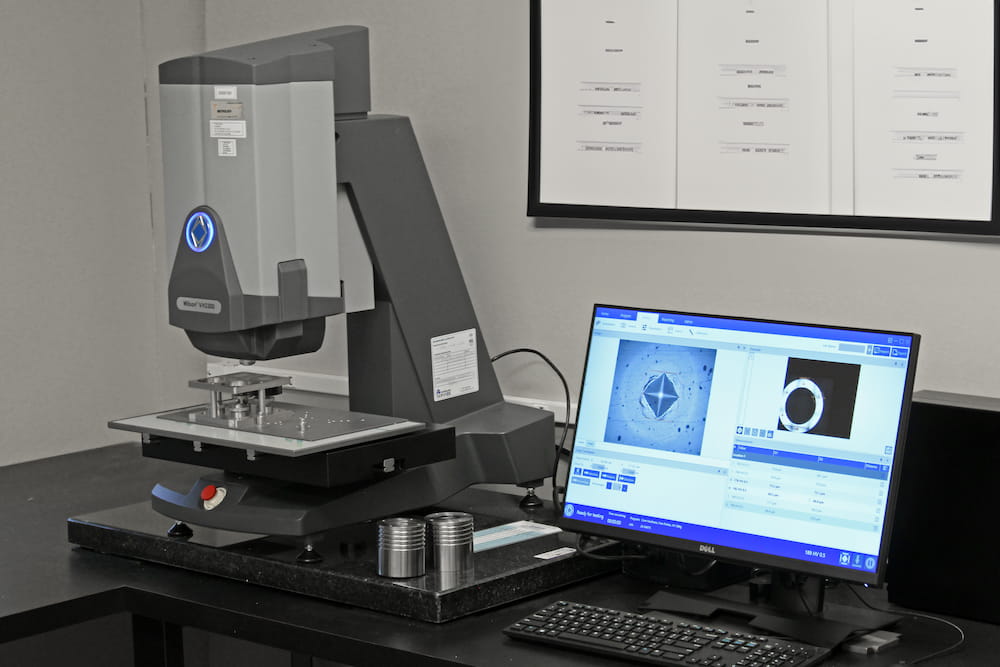

Hardness measures a material’s resilience to metal deformation from indentation or abrasion. Hardness is a complex material property due to ductility, toughness, viscosity, and more. Fortunately, measuring hardness is relatively straightforward, relying on a sample’s scratch, indentation, or rebound process. Microhardness testing uses high-powered optical resolution to determine the depths of material deformation and is one of the test services available at Lab Testing Inc.

Microhardness Testing Processes

Types of Microhardness Testing

Knoop |

Vickers |

| The Knoop hardness test apparatus applies a controlled force for a specific time to an indenter in a rhombus shape (elongated four-sided pyramid). The depth to which the Knoop indenter penetrates indicates the hardness of the material. The impression is measured microscopically and, when combined with the amount of the test load, can be used to calculate the hardness value on the Knoop scale. Knoop hardness numbers must indicate the load values. | The Vickers hardness test is available on the micro and macro scales. Like Knoop microhardness testing, these tests apply controlled pressure for a standard time but with a square-based diamond pyramid indenter. A microscope measures the diagonal of the resulting indentation, which combines with the test load to calculate the Vickers hardness value. |

Hardness Conversion Charts comparing microhardness test values to tensile strength and other hardness scales (e.g., Rockwell) are available.

Specifications

- ASTM E92

- ASTM E384

- ASTM E1077

- ASTM B578

- ASME Sect. IX

- MIL Specifications

- ISO 6507 / ISO 9015

Capabilities

Partner With a Leading Material Lab Testing Facility

Partner With LTI Today

Laboratory Testing Inc. has the capacity and capabilities to handle all your material testing needs in a single location. Since 1984, we’ve aided customers worldwide with accurate nondestructive testing and precise material lab services. Request a quote or contact us today to see how our industry-leading turnaround times can keep your mission-critical approvals moving forward.