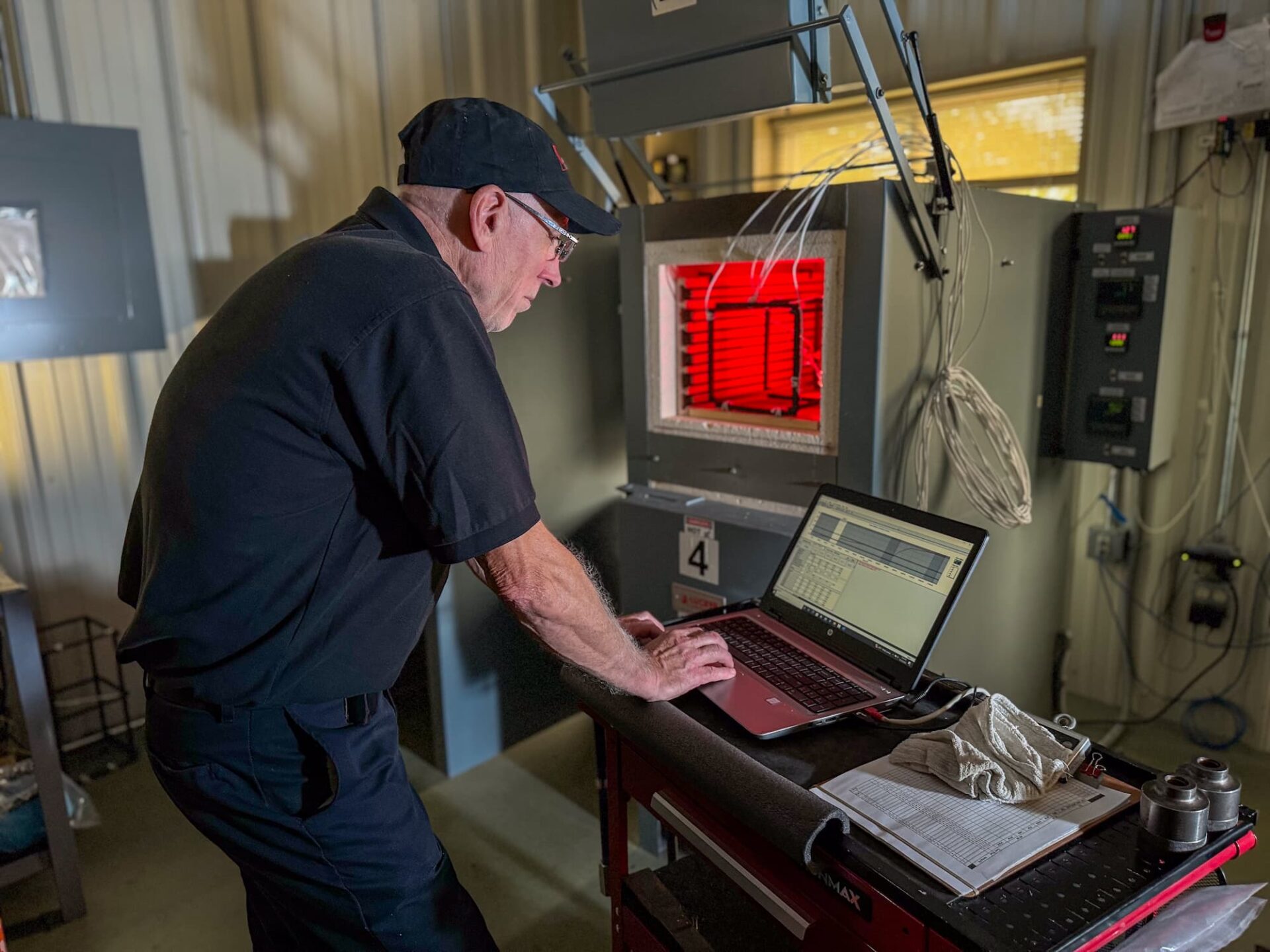

Laboratory Testing Inc. offers a wide variety of heat treatment testing and calibration services for the greater Philadelphia area. We offer a variety of specialized tests, including hardness and tensile testing, metallography, chemistry, AMS 2750 calibrations, and more!

LTI Advantages

Rapid Turnaround Time:

LTI understands the importance of timely results in the manufacturing and heat treatment industry. With efficient processes in place, LTI aims to provide rapid turnaround times for test results, enabling heat treat facilities to make informed decisions and maintain production schedules.

Robust Customer Portal:

LTI provides a user-friendly customer portal that offers convenient access to test results, reports, and project information. This portal streamlines communication and data retrieval, enhancing the overall customer experience and allowing heat treat facilities to track and manage their testing projects with ease.

Comprehensive Expertise:

LTI boasts a team of experienced metallurgists and technicians with in-depth knowledge of various metals and their response to heat treatment processes. This expertise enables them to provide precise and reliable testing services, helping heat treat facilities certify materials to specific requirements.

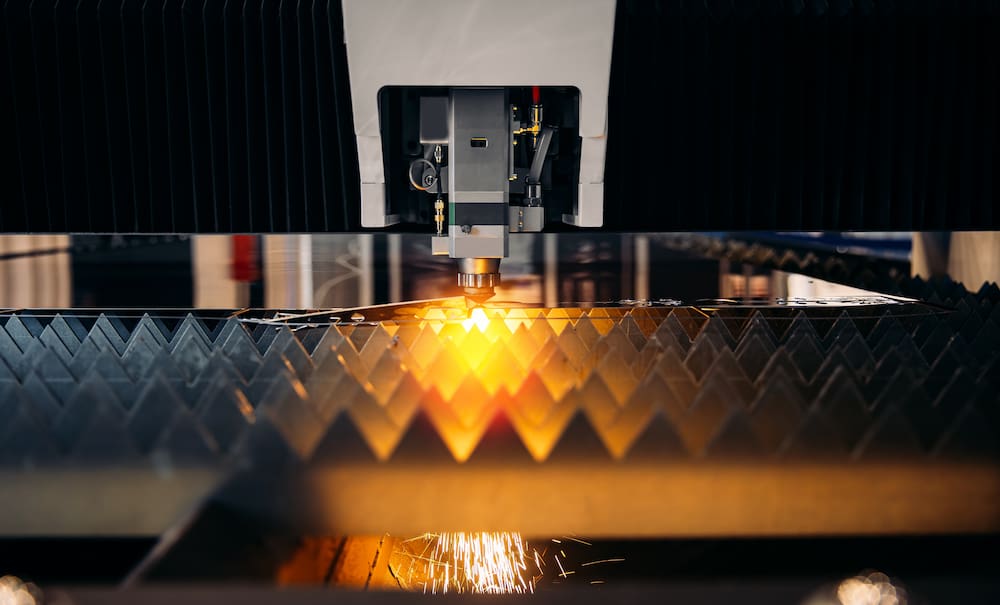

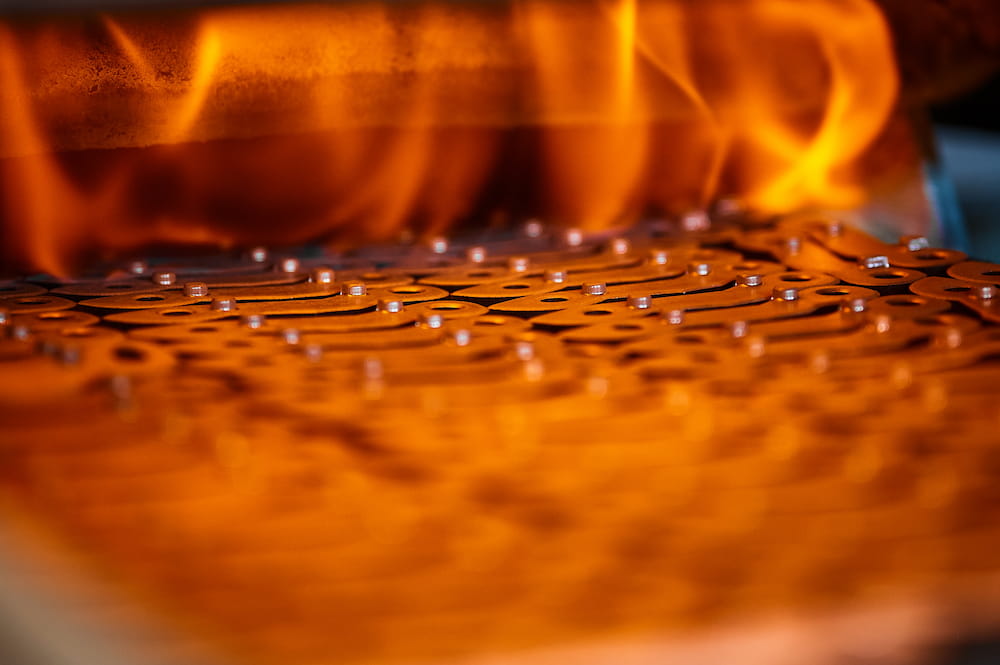

Heat Treatment Verification Testing Services

Temperature Calibration Services

Industries Where We Work

The LTI Advantage

Laboratory Testing Inc. has the capacity and capabilities to handle all your material testing needs in a single location. Since 1984, we’ve aided customers worldwide with accurate nondestructive testing and precise material lab services. Request a quote or contact us today to see how our industry-leading turnaround times can keep your mission-critical approvals moving forward.