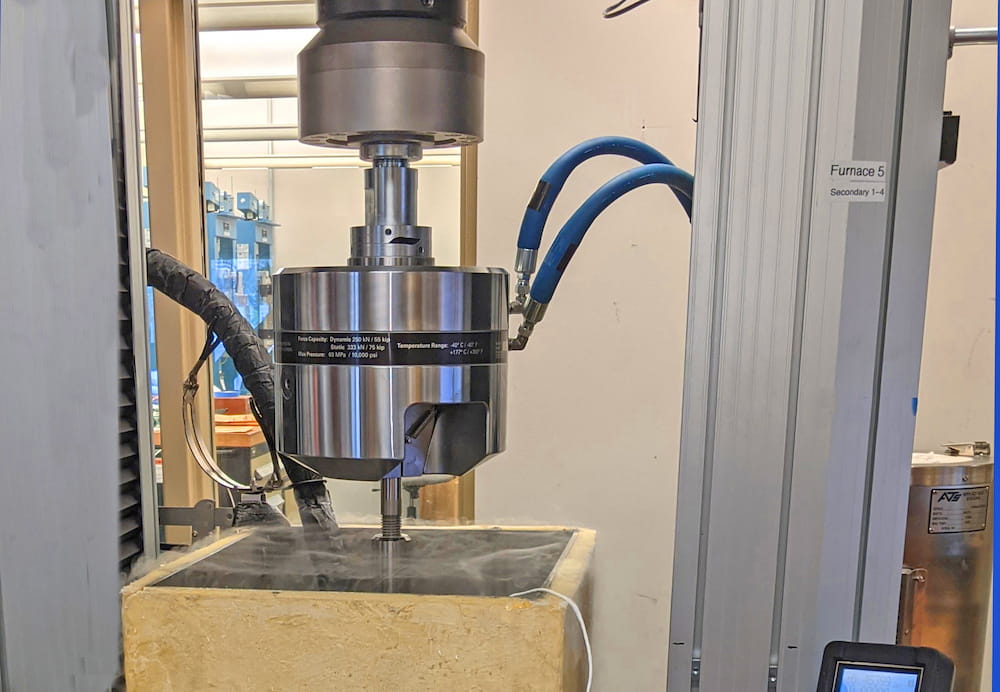

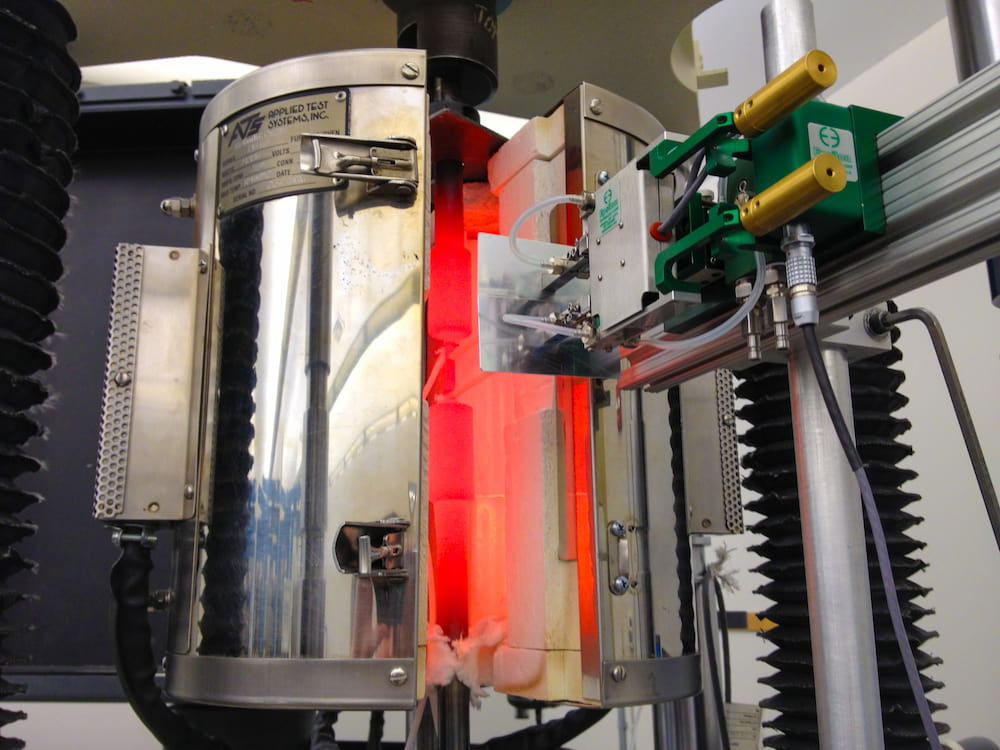

People rely on structures daily to bear weight and hold shape under tension. An integral approval for the materials and products used in these structures are tension tests that ensure suitability at a particular loading. A tensile testing lab is necessary to characterize a wide swath of materials, both at low- and high-temperature extremes, to observe the effects on tensile and yield strength.

The Tensile Test Process

Sub Ambient (LN2) and Elevated Temperature Tensile Testing

Specimen Type

- Wedge & axial tensile

- Full-size yield strength of fasteners

- Machined specimens

- Full-size tubing

- Full-size rebar

- Welds and castings

Specifications

- ASTM A370

- ASTM B557

- ASTM D638

- ASTM E8

- ASTM E21

- EN 2002-1

- EN 10002-1

- ISO 527-1

- ISO 6892-1

- Fasteners: ASTM A962, ASTM F606, ASTM F835, ISO 898-1, ISO 898-2, NASM-1312-8 (Formerly MIL-STD-1312-8), SAE J429, SAE J995

Capabilities

A Leading Materials Testing Lab in Greater Philadelphia

Partner With LTI Today

Laboratory Testing Inc. has the capacity and capabilities to handle all your material testing needs in a single location. Since 1984, we’ve aided customers worldwide with accurate nondestructive testing and precise material lab services. Request a quote or contact us today to see how our industry-leading turnaround times can keep your mission-critical approvals moving forward.