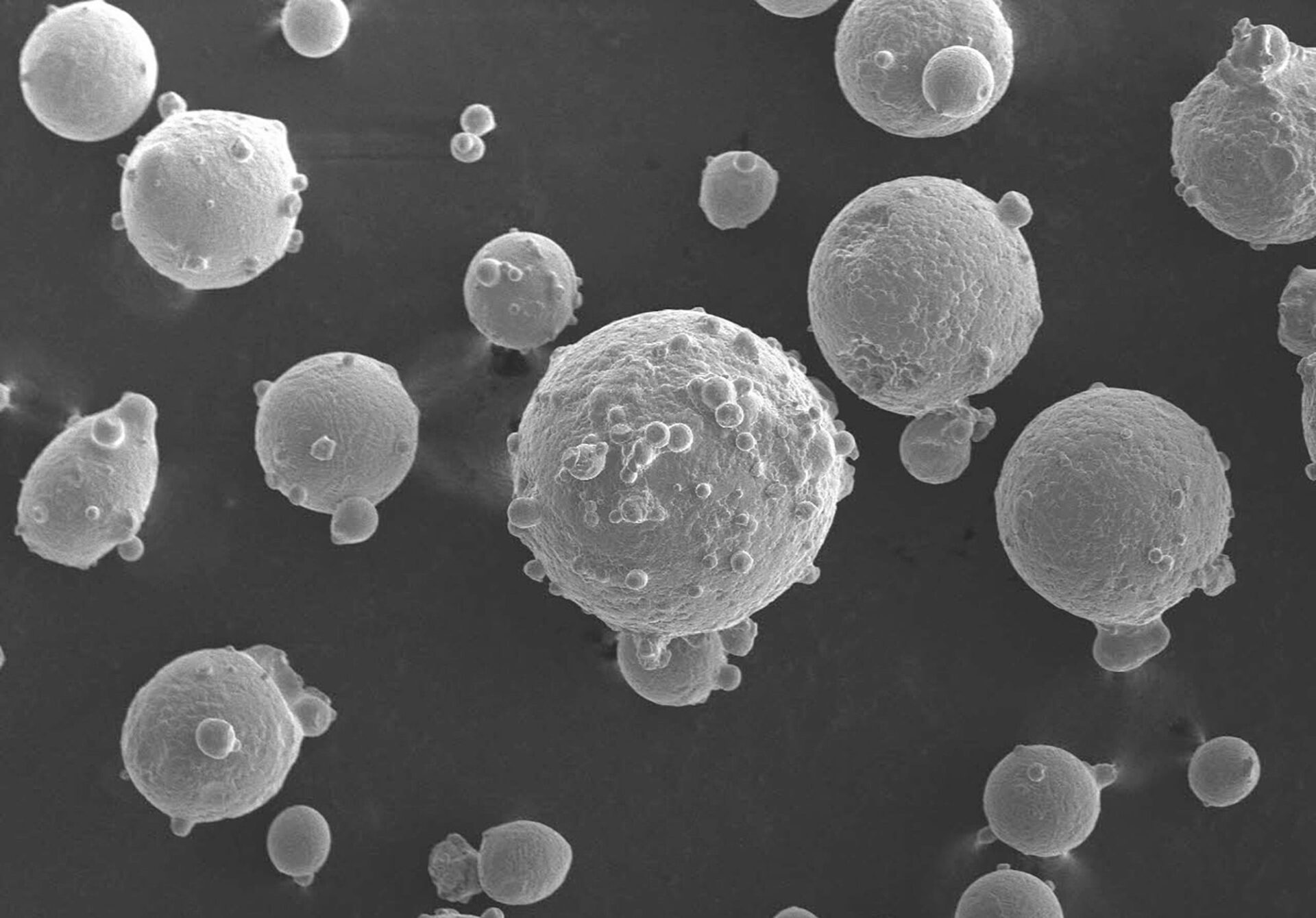

What happens when typical optical resolutions are not enough? Visualization of sample microstructures can exist on the order of micrometers and even less. To understand these features better, material labs can use scanning electron microscopy or SEM analysis to transform electron interactions at the surface into a topography map. SEM is unparalleled in its resolution capabilities as a visualization tool compared to standard microscopy techniques.

SEM EDX analysis provides valuable information for metallurgical testing and elemental composition analysis. It is also helpful for investigating material failures since it can reveal where a fracture started, how fast it propagated, and whether the fracture mode was ductile or brittle. This instrument can also record cross-sectional measurements of plating thickness (ASTM B748). The results are in the form of black-and-white images for our interpretation.

The SEM Analysis Process

Scanning electron microscopy uses a focused beam of high-energy electrons to generate various signals at the surface of solid specimens. In most SEM applications, data collects over a selected area of the sample’s surface and creates a two-dimensional image that displays spatial variations in properties, including chemical characterization, texture, and orientation of materials. The SEM can also perform analyses of selected point locations on the sample. This approach is handy in qualitatively or semi-quantitatively determining chemical compositions, crystalline structure, and crystal orientations.

The EDX detector separates the characteristic X-rays of different elements into an energy spectrum. During SEM EDX Analysis, an electron beam scans across a sample’s surface, and the electrons strike and stimulate the sample. Almost instantaneously, as each element returns to its original energy state, it emits X-rays of specific energies at different wavelengths characteristic of the element–a typical EDX spectrum portrays a plot of X-ray counts vs. energy (in keV). Energy peaks correspond to the various elements in the sample. Energy dispersive x-ray spectroscopy can find the chemical composition of materials down to a spot size of a few microns and create element composition maps over a much broader raster area.

Capabilities

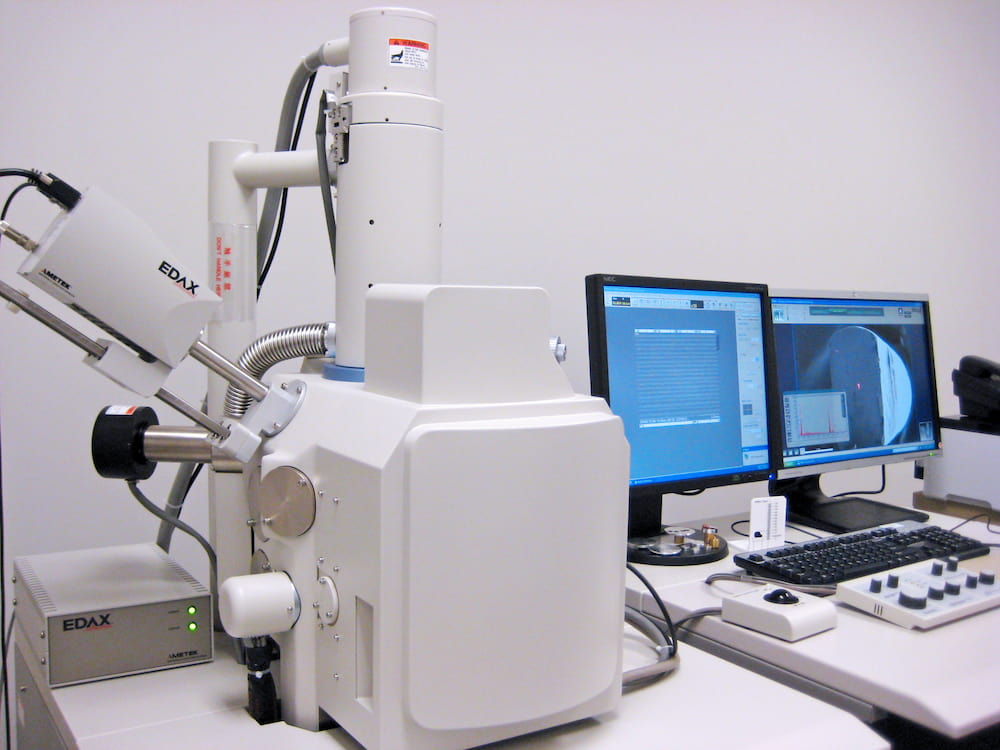

- The Hitachi SEM features a variable pressure system accommodating wet and non-conductive samples with minimal preparation.

- SEM can produce high-resolution images at magnifications from 5x to 300,000x.

- The large sample chamber allows for the examination of samples up to 200 mm (7.87 in.) in diameter and 80 mm (3.14 in.) in height.

- Suitable for metal and polymeric sample analysis.

- The EDX component couples with SEM analysis to detect and measure elements in or on the sample’s surface for qualitative analysis and quantitative information on a sample’s elemental composition.

- The new SEM and EDAX equipment is beneficial in microanalysis and analyzing small areas of interest in samples.

- The system uses the new TEAM software package that facilitates material characterization via spectral analysis, line scans, and element mapping methods.

Specifications

- ASTM B748

- MIL Specifications

LTI Is an Industry Leader in Materials Testing

Partner With LTI Today

Laboratory Testing Inc. has the capacity and capabilities to handle all your material testing needs in a single location. Since 1984, we’ve aided customers worldwide with accurate nondestructive testing and precise material lab services. Request a quote or contact us today to see how our industry-leading turnaround times can keep your mission-critical approvals moving forward.