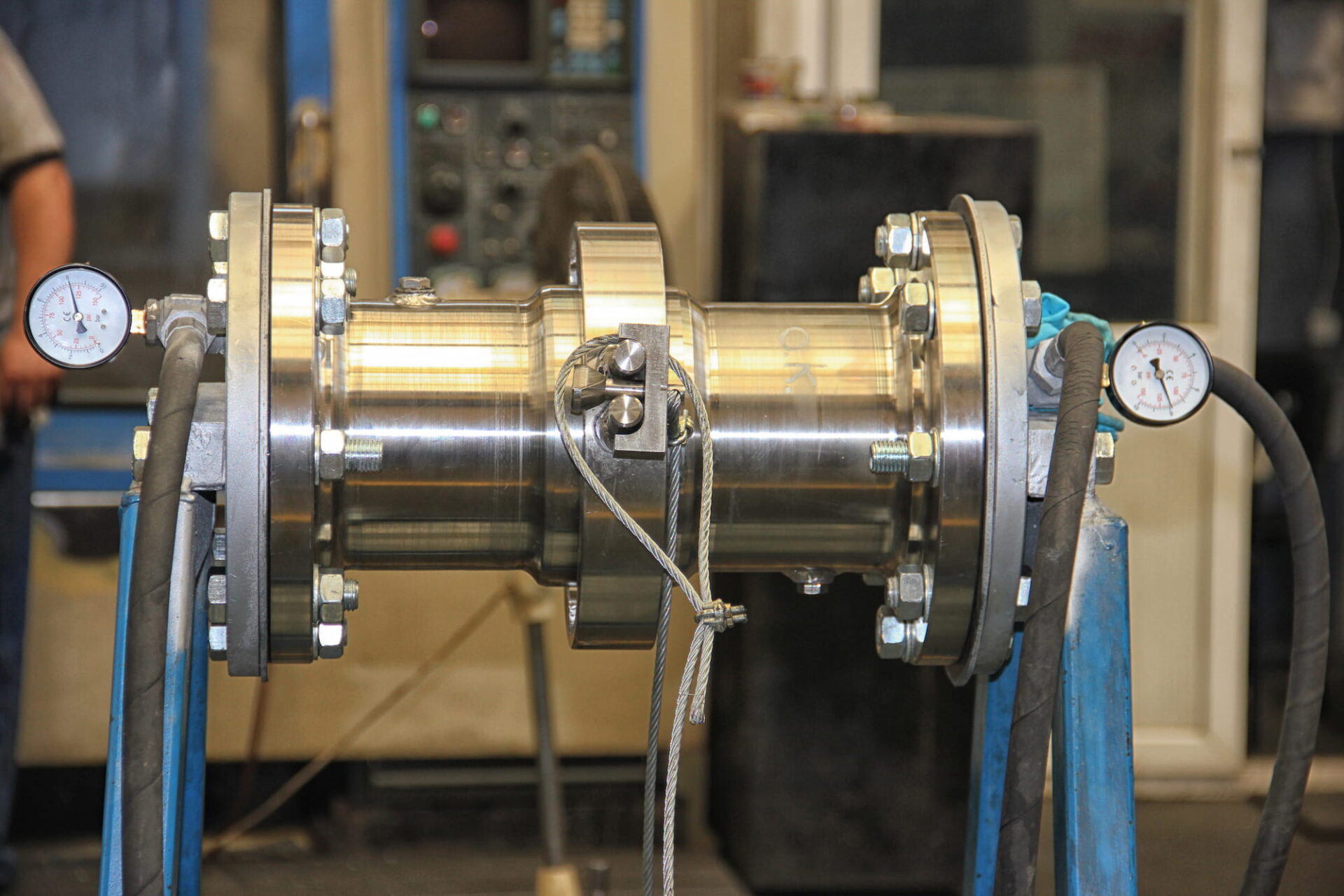

Hydrostatic pressure testing, also known as hydrostatic testing or leak testing, provides a method for finding leaks or verifying performance and durability in pressure vessels. The hydrostatic pressure test is classified as one of LTI’s nondestructive testing techniques, meaning the sample is typically not harmed during the test.

Hydrostatic Pressure Testing at LTI

Capabilities

- Products Tested – tubing, pipe, coils

- Testing Medium – water, oil, air (under water)

- Pressure to 10,000 PSI

Standards

- ASTM

- ASME

- AMS

- MIL specifications

The LTI Advantage

Partner With LTI Today

Laboratory Testing Inc. has the capacity and capabilities to handle all your material testing needs in a single location. Since 1984, we’ve aided customers worldwide with accurate nondestructive testing and precise material lab services. Request a quote or contact us today to see how our industry-leading turnaround times can keep your mission-critical approvals moving forward.