Mechanical performance is directly tied to a material’s properties. The best way to assure the performance of test materials or developed products is with a rigorous characterization through a series of destructive tests that identify breaking points. For all materials, a profile through various mechanical testing lab evaluations will aid design teams in selection criteria to optimize product applicability.

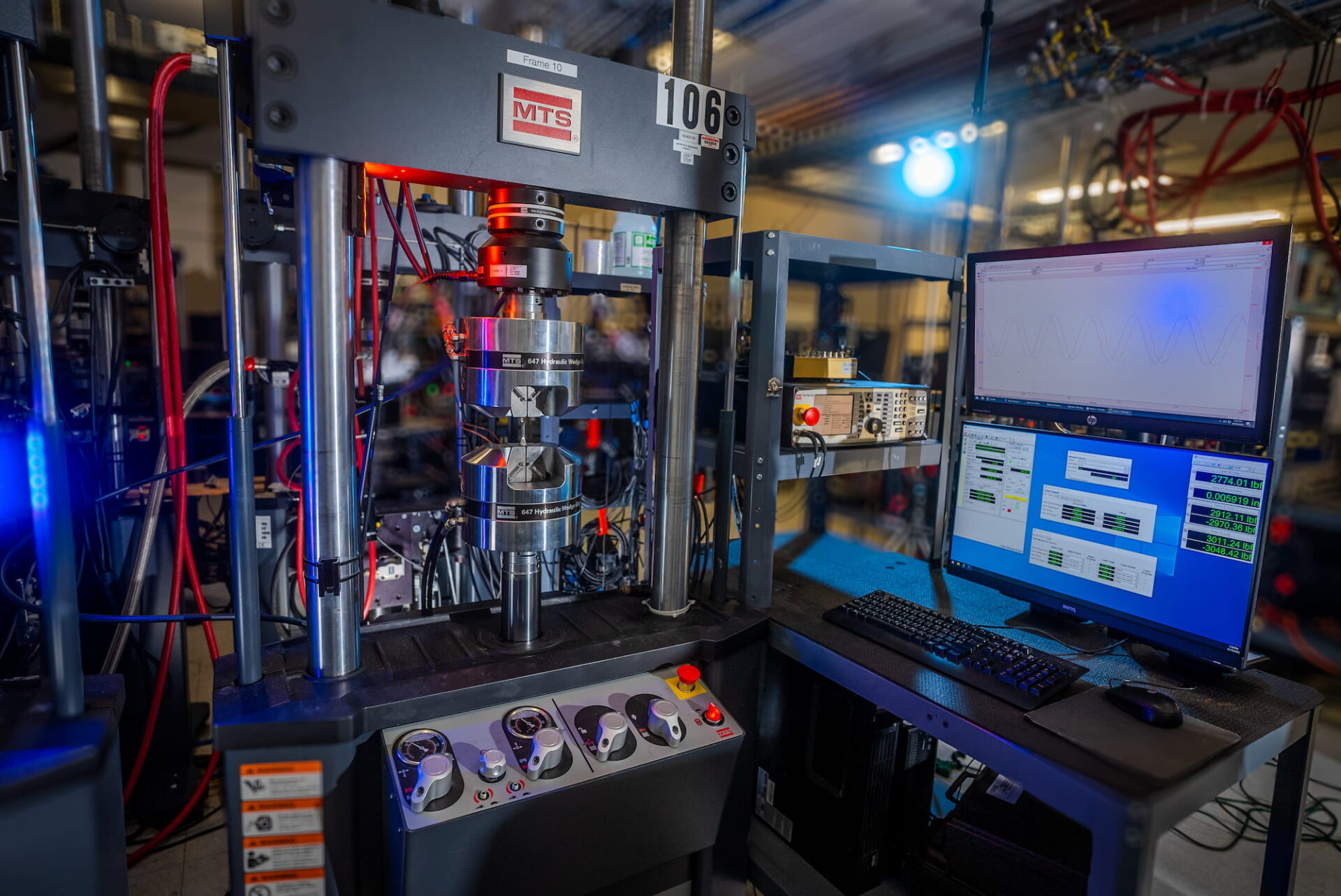

LTI’s Mechanical Testing Lab

Capabilities

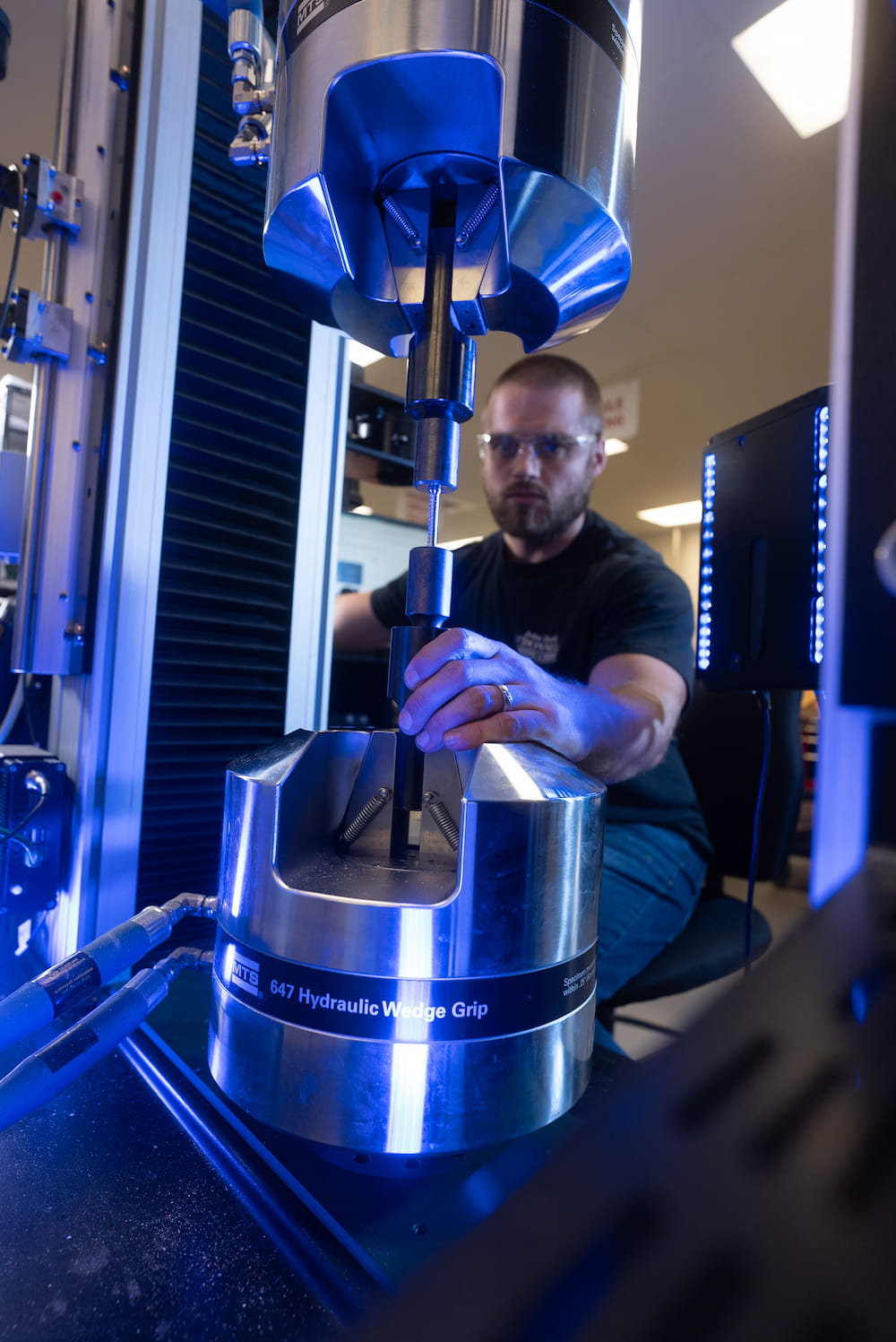

Tensile Testing:

Our advanced Tensile Testing machines, ranging from 8 ozs. to 600,000 lbs., assess the strength of various materials. We also offer plastics testing with a 10,000 lb. capacity tensile machine

Elevated and Sub-Ambient Temperature Tensile Testing:

Experience precise Elevated Temperature Tensile Testing with our furnace carousel, capable of processing up to three specimens simultaneously, with test samples heated to temperatures as high as 1800°F.

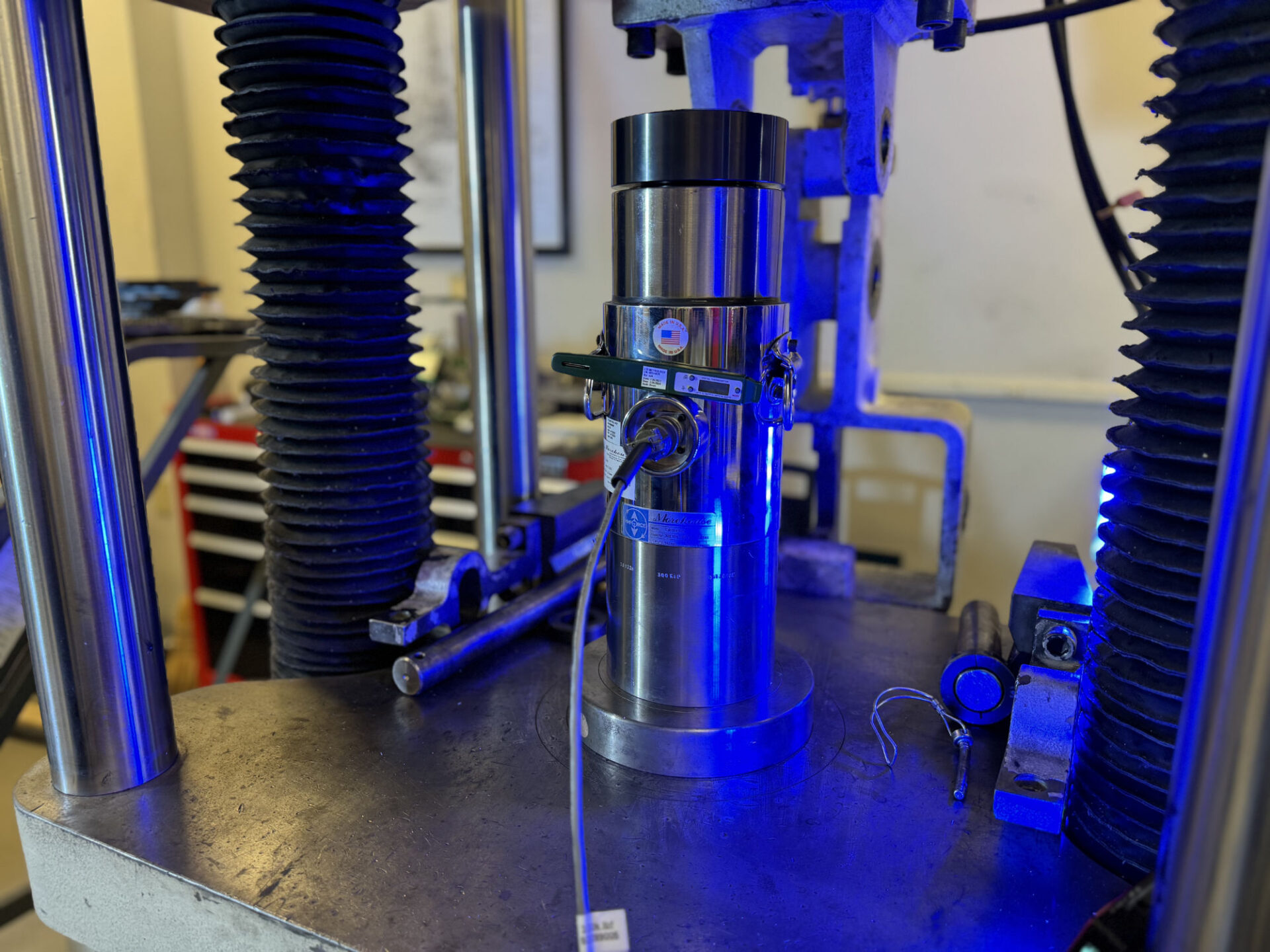

Stress Rupture and Creep Testing:

Our Stress Rupture and Creep Testing adhere to ASTM standards and can be conducted at temperatures reaching up to 2000°F.

Fatigue and Facture Testing:

Using equipment capable of generating up to 100,000 lbf., we offer Fatigue Crack Growth, Fracture Toughness and High/Low Cycle Fatigue Testing, controlling test temperatures from sub-ambient to elevated temperatures.

Impact Testing of Metal:

Our Impact Testing services cover a wide temperature range from -452°F to +500°F, offering impact energy of up to 320 ft. lbs. We conduct Charpy V-notch, weld charpy, and drop-weight testing.

Hardness Testing:

We provide a range of Hardness Testing options, including Rockwell, Brinell, and Superficial Hardness Testing for metals, as well as the Shore Durometer test for plastics.

Welder & Procedure Qualification:

Our comprehensive Welder & Procedure Qualification services meet various specifications, codes, and standards, including MIL, API, ASME, AWS, ASTM, EN, and the Pressure Equipment Directive.

Test Specimens for Mechanical Testing:

Our fully-staffed Machine Shop operates on two shifts to prepare precision test specimens for all mechanical testing needs. Specimens are machined according to ASTM standards.

Heat Treat Capabilities:

In-house capabilities to process metals through process such as annealing, normalizing, hardening, and tempering with capacity of over a dozen furnaces.

Tube Testing

- Flaring

- Expansion

- Flattening

- Tensile testing (full-size tubing)

Fastener Testing

- Yield strength

- Axial and wedge tensile

- Proof loading

- Cone strip test

- Double shear

- Flattening

- Hardness testing

- Magnetic permeability

- Hydrogen embrittlement/stress durability

- Tension fatigue

Other Services

- Hydrogen embrittlement/stress durability conductivity

- Magnetic permeability

- Compression testing (per ASTM E9)

- Proof loading

- Bending

- Hardness testing (Rockwell, Superficial Rockwell, Brinell, Vickers and Knoop microhardness)

- Stress rupture

- Creep testing

- Fracture and fatigue testing (crack growth, fracture toughness, high- and low-cycle fatigue)

- Impact testing (Charpy U- and V-notch, drop weight)

- Tensile testing (machined specimens, full-size rebar and tubing, elevated temperature)

- Shear testing (per ASTM B769 & B831)

- Pin-type bearing testing (per ASTM E238)

- Welder and procedure qualification

Quality and Qualifications

LTI Is Your One-Stop Solution for Material Testing

Partner With LTI Today

Laboratory Testing Inc. has the capacity and capabilities to handle all your material testing needs in a single location. Since 1984, we’ve aided customers worldwide with accurate nondestructive testing and precise material lab services. Request a quote or contact us today to see how our industry-leading turnaround times can keep your mission-critical approvals moving forward.