LTI: A Nadcap & A2LA Accredited Lab

Your trusted partner for material testing and calibration services, serving MISSION CRITICAL industries

As leading industry experts in material testing for mission-critical industries, Laboratory Testing Inc. offers tailored service models to meet your specific application and testing criteria. Our goal: To be a one-stop solution for uncompromised quality, precision, and turnaround times to ensure your success.

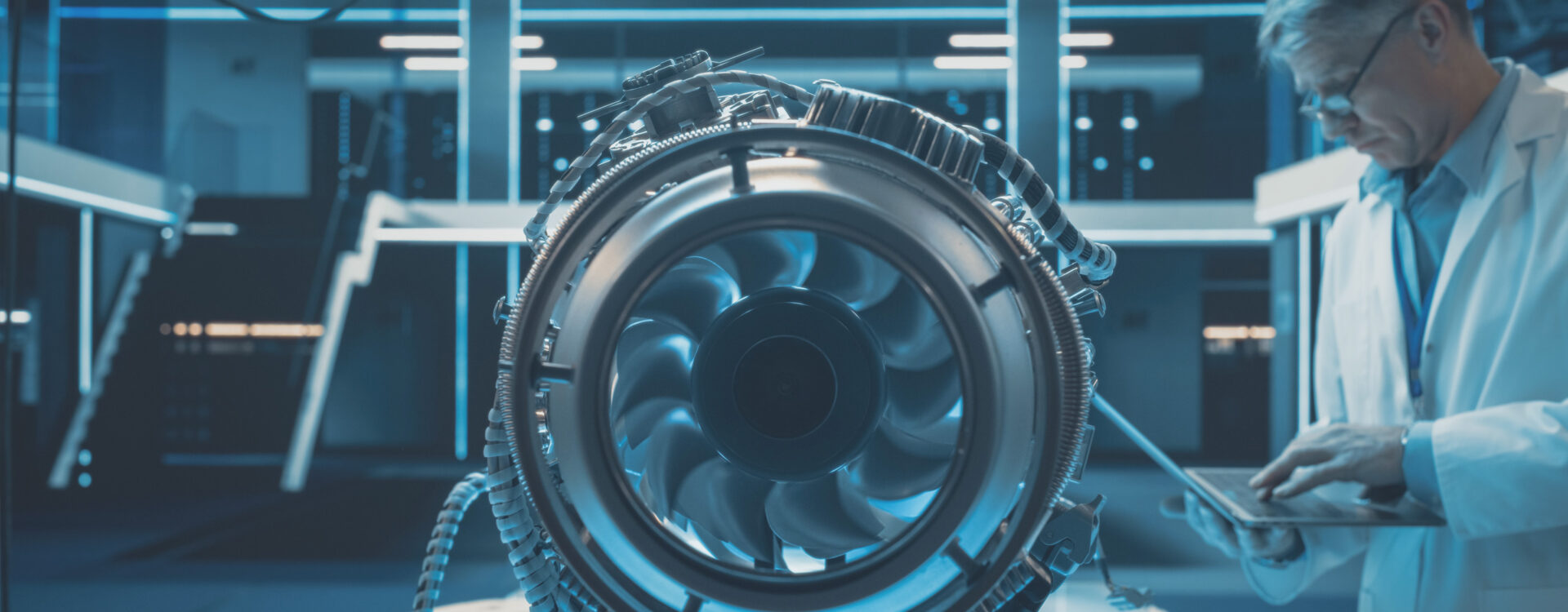

At Laboratory Testing Inc., we redefine excellence in metal testing, serving dynamic industries such as aerospace, military, and space. Our commitment to accuracy, innovation, and efficiency is the foundation of our services. We are your destination for cutting-edge Non-Destructive Testing, Material Testing, and Calibration solutions, whether you need R&D testing, complex material characterization projects, or production testing with unrivaled schedule delivery & transparency.

Metals

& Material Testing

LTI inspects and tests metal parts and products in all shapes and sizes with various services, including mechanical testing, metallurgical analysis, chemical testing, and corrosion analysis. All results are documented in detailed Certified Material Test Reports.

Metrology

& Calibration

The Metrology Services offered by Laboratory Testing Inc. include Dimensional Inspection and Calibration Services. The Lab holds A2LA accreditation to ISO 17025:2017, and all inspection results are traceable to NIST.

Approvals

& Accreditations

LTI has Nadcap accreditation for materials and nondestructive testing as well as A2LA accreditation ISO/IEC 17025:2017 for materials testing, dimensional inspection, and calibration services.

LTI is also compliant with ISO 9001 and ISO 13485.

We are approved as a supplier for many businesses and industry organizations.

Who We Are

Laboratory Testing Inc. (LTI) is a global leader in material testing and calibration services. We are one of the largest independent testing laboratories, and our facility can handle materials and finished parts of all shapes, sizes, and quantities.

What We Do

All material testing and calibration services are provided at our cutting-edge facility, allowing customers to achieve all of their testing needs under one roof. The result is a faster, more efficient process to meet critical deadlines.

- Chemical Analysis

- Metallurgical Testing

- Mechanical Testing

- Corrosion Testing

- Fatigue Crack Growth

- Testing Calibration

- High and Low Cycle Fatigue Testing

- Specimen Machining

- Ultrasonic Testing

- Calibration

- Non-Destructive Testing

Industries

LTI’s state-of-the-art materials testing lab helps drive innovation in these critical industries.

Working at LTI

At LTI, we believe caring for our customers starts with caring for our employees. We’re a passionate group of professionals always looking for talented individuals committed to supporting and performing material testing excellence. Some of our benefits include:

- Competitive Compensation

- Medical / Dental / Vision Package

- 401K Savings with Company Match

- Annual Incentive Bonus

- And More

Partner with LTI Today

No matter how intricate or complex, LTI is ready to meet your most challenging material testing requests. Learn why LTI has made its name as a leader in materials testing globally.

Laboratory Testing Inc. has the capacity and capabilities to handle all your material testing needs in a single location. Since 1984, we’ve aided customers worldwide with accurate nondestructive testing and precise material lab services. Request a quote or contact us today to see how our industry-leading turnaround times can keep your mission-critical approvals moving forward.